Supply chain management (SCM): what is it and what does it do?

Well-developed supply chains can make or break a company. Especially during a crisis, the right strategy can mean continued sales – despite challenges in logistics or production. By way of efficient supply chain management, large international corporations can make use of alternative delivery interfaces, big data analytics, and detailed information surrounding the availability and demand for goods from global suppliers.

The synchronization of cross-company information and goods flows can not only strengthen a company's ability to adapt to flexible market conditions, but also helps maintain relationships with suppliers, manufacturers, and end customers during a crisis.

But what exactly is supply chain management? How does it work? And why is it also of great importance for e-commerce?

What is supply chain management (SCM)?

Global supply and production chains and increasing digitalization are not just a challenge for companies, but also an opportunity. By organizing the future flow of goods and information through supply chain management, companies can not only balance out market uncertainties but also create a flexible network of services.

Supply chain management represents the overview and optimization of physical and digital supply chains, from raw material suppliers to the end consumer. An efficient SCM enables supply and production processes at competitive prices and a constant flow within the value chain. Here, it’s not about optimizing the weakest link in the supply chain, but that every link plays its part.

An open and transparent exchange of information between dealers, suppliers, and producers guarantees that companies can react flexibly and quickly to fluctuations in demand, as with the bullwhip effect. This ensures that the flow of goods is as uninterrupted as possible and inventories don’t accumulate. The supply chain can only be made more efficient if short communication channels, big data analytics, and innovative technologies are used to influence suppliers and the flow of goods.

Central to efficient supply chain management is the implementation of modern information and communication technology in the form of software solutions and machine learning. The faster, more uniform, and automated the data exchange, the better the links in the supply chain interlock.

The goals of supply chain management – simply explained

Product life cycles and turnaround times are becoming ever shorter in our globalized world, while customer expectations continue to increase and the need for cheaper production and fast delivery times grow. Supply chain management can establish a transparent network along the entire value chain by way of stability and cooperation.

Key goals of SCM are lower costs, customer focus, and demand-oriented production through an effective division of labor. Companies can only make physical and logistical infrastructures cheaper, faster, and more competitive by cooperating with partners and making information transparent.

The division of labor lets partner companies concentrate on their core competencies. A product is no longer manufactured centrally. Instead, components and raw materials are brought in by producers, suppliers, and sub-contractors at the best price-performance ratio and delivered to the end customer as a finished product. However, it is the integration of big data analytics and machine learning that makes it possible to synchronize demand and supply, and balance production with demand.

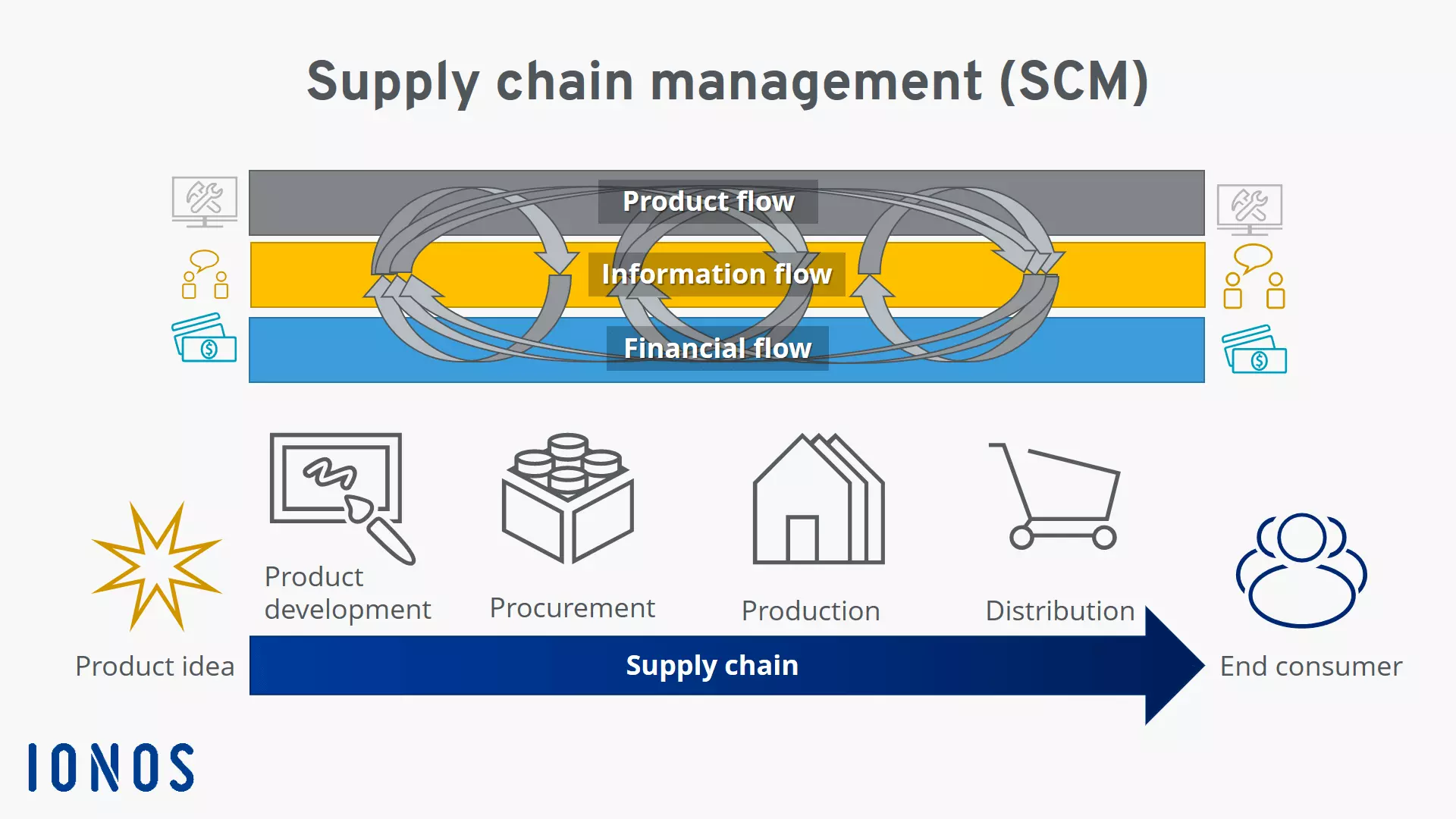

The three fields of application of supply chain management (SCM)

SCM can be split into three fields of application:

Product flow: Not only do companies need to maintain a good relationship with affiliate companies; companies also need to know which sub-contractors are used along the supply chain. Only if they are fully aware of a product’s journey from the raw material suppliers to manufacturing and to the end consumer can they manage the product flow of deliveries and returns.

Information flow: Information must flow in two directions along the supply chain. To deliver products efficiently, companies must rely on customer behavior. How much are they buying? Are there places where consumers request certain products? Are there regular peaks in demand? These transfers of data from sales outlets to companies make sure supply flows are effectively managed. Information about transport routes and a comprehensive communication infrastructure are an integral part of SCM.

Financial flow: Financial flows take place parallel to and in connection with production processes. Each link in the value chain has its own financial interests and wants to benefit from the cooperation. The control and optimization of financial flows is essential for SCM in order to reduce costs and increase profits for all involved.

Supply chain management along the value chain

Product development: In the early development phase, SCM ensures that suitable suppliers and manufacturers are identified and put together. Demands for product quality and cost efficiency can already be implemented in this early phase.

Procurement: To make material procurement and storage as seamless and cost-effective as possible, SCM centralizes and organizes logistics, purchasing, and management concepts for suppliers, manufacturers, and customers.

Production: SCM monitors quality requirements for materials, production, packaging, and services, and optimizes the flow of goods through transparency and the evaluation of results.

Distribution: SCM continuously evaluates and optimizes warehousing, supply companies, and transport routes to find the best possible goods routes from production to the consumer.

Phases of supply chain management (SCM)

Supply chain management has three phases:

In the strategic phase, a company makes long-term decisions over months and years to optimize and stabilize the logistics network along the value chain (e.g. location planning and expansion, investments, outsourcing, capacities).

In the tactical phase, medium-term decisions are coordinated and implemented within a quarter or a year (e.g. delivery strategies, warehouse logistics, personnel planning).

In the operational phase, short-term production and delivery decisions are made within days or weeks (e.g. product sales and storage and order distribution).

Although supply chain management and logistics are similar, they deal with different areas. Logistics is mainly concerned with the actual delivery of goods or materials. SCM, in turn, deals with the functional aspect of value creation and focuses on cost, profit, and process optimization.

Supply chain management: explanation of software solutions

To implement SCM, effective and innovative technologies and strategies are needed. Here, modules and applications are interconnected to implement company-wide planning concepts in a uniform and process-oriented way. This includes product and financial flows, resource optimization, data transfers, and logistics. Companies like Amazon and Netflix have long made use of big data analytics, real-time content, and systems of engagement to evaluate user data and interests, and derive appropriate measures.

According to a global research study on the current and future state of digital supply chain transformation, 70% of executives from some of the largest global manufacturing and retail organizations said that they have initiated a digital supply chain transformation and that dramatic changes are expected within just 5 years. While only 23% of respondents said that currently most data is analyzed and used for decision-making, within 5 years that number jumps to 68%.

The key components that make up successful supply chain management include big data analytics, cloud computing, simulation tools, real-time content, bimodal strategies, and a strong customer focus. The monitoring of one's own products could be increased, for example, with RFID technologies (Radio Frequency Identification), in which information on purchasing behavior and demand reaches manufacturers and suppliers directly.

Transforming a company through supply chain management requires that complex changes be made to its IT systems and communication streams along the supply chain, making it a challenging transition.

The importance of supply chain management to businesses

In light of growing global protectionism and the severe blows that have hit global trade in recent years, many companies have no choice but to familiarize themselves with SCM. Due to ever-shorter market launches and product life cycles, lowering costs and increasing profits without constant contact to national or international partners is almost impossible to achieve.

Particularly during a crisis or in uncertain markets, changes to delivery routes and production figures are necessary to reduce inventories and maintain the flow of goods. Be it Walmart, Tesla, Apple, or Amazon – big players on the market have for a while already made innovative technologies, artificial intelligence, and automation part of their business model.

What are the disadvantages of supply chain management?

Common issues that arise due to supply chain management include:

- Clashing company goals: Along the supply chain, conflicting business objectives can clash

- Distribution of costs/tasks/responsibilities/profits: The fair or equal distribution of tasks, costs, and responsibilities links all those in the supply chain

- National and international standards: Agreeing on company-wide standards for the entire planning process

- Data security: The safeguarding of internal financial and production data and internationally differing safety standards

- Lack of proximity: Maintaining close and transparent cooperation across borders without direct contact

Supply chain management in e-commerce

In our globalized world, e-commerce is growing in importance. The buying and selling of goods and services via online shops and internet platforms can be controlled by means of an advanced SCM. Key elements for adaptable and forward-looking e-commerce platforms include a transparent overview of stock levels, a demand for goods, and the ability to estimate scalability.

The timely implementation of supply chain management can improve sales forecasting and make production needs more predictable. For e-commerce, specifically, the advantages include customer proximity as well as the fast evaluation of big data and buying behavior. Due to these factors, SCM is very well suited to online sales.

- Get started with stunning designs

- Grow with advanced marketing and admin tools

- Sell on social and online marketplaces

Tips for supply chain management in e-commerce

To successfully apply SCM in e-commerce, it’s important to take certain factors into account.

Personnel management and digital infrastructure: To guarantee reliable supply chains, it’s important to build a flexible network of manufacturers and suppliers that can keep pace with the demands of a growing company. In international trade, it is of great importance to exchange information with experts who can advise on issues relating to contractual obligations, currencies, and customs.

Availability of goods and delivery times: Customer expectations are extremely high in the face of competitors like Amazon Prime. Short delivery times, low prices, and high quality are decisive factors for most consumers. Competitive business is only possible when an effective logistics chain, forward-looking inventory management, and structural adaptability by way of alternative sub-contractors are in place.

Reduce excess stock: In order to reduce old stock and unnecessary costs, overstocking must be avoided and inventories must be adjusted to the demand for goods. With the evaluation of customer data and an overview of warehouse capacities, manufacturers and suppliers can flexibly navigate the e-commerce market.

Manage returns: Especially in online sales, customers expect returns to be handled without problems. Favorable conditions with your own suppliers in terms of returns are therefore particularly important for achieving a balance between business losses and good customer service.

E-commerce and supply chain management make a great team. When choosing an online shop with IONOS, you can get your e-commerce business started with easy- drag-and-drop modules and stunning designs.